If you are using a medium-voltage drive to control a motor of 1,000 hp or less, you should ask yourself, “Why?”

%201.png)

In the days before variable frequency drives, it was impractical to use large motors on 480V systems because of the cost and the disruption that inrush would cause to the grid.

Before variable frequency drives became more widespread, it was common to

use a medium-voltage starter to control large motors. It was the only option, really.

Low-voltage drives flipped the math and completely eliminated inrush.

However, some specifications have been stubbornly hanging on to using

medium-voltage controllers because of limitations that date back to the

1960s. Let’s think about a technology invented in 1960 that we still use

today. Can you think of any? We would say not many, so why use old

technology in your modern oilfield.

Times—and more importantly, the technology—have changed. Today,

low-voltage drives make more sense from almost any perspective for

motors of 1,000 hp or less.

The math is simple and undeniable.

Consider first, the cost of a medium-voltage motor compared to a low-voltage motor:

800 hp 4160V Motor

Net Price:

$53,635

800 hp 480V Motor

Net Price:

$44,745

Savings on

the motor:

the motor:

$8,890

A typical VFD comparison

Consider a typical situation in a typical oilfield. What we have here are two drive solutions, one 4160V, one 480V. Both are used in upstream and midstream applications on motors with 1,000 hp or less. But when you study the comparison, the only question you should ask is, “Why?”

.png?width=390&height=289&name=Group%2011%20(1).png)

4160V Drive

4160V 101A maximum NEMA 1 VFD inside of A/C structure

VFD Losses:

A/C Power Consumption:

Total Losses:

18.4kW (assumed 95% motor efficiency)

7kW

25.4kW per pump, 96% system efficiency

480V Drive

VFD Losses:

A/C Power Consumption:

Output Reactors:

Total Losses:

11.8kW (assumed 95% motor efficiency)

2.2kW

.5kW

14.5kW per pump, 97.7% VFD efficiency

480V drives are the smarter choice for

three provable reasons:

three provable reasons:

Initial Cost: 4160V drives cost more

Medium-voltage drives cost more than low-voltage drives. Significantly more. The drive costs more, and you need more infrastructure to house and protect the drive. True, it costs less to install a medium-voltage drive, but that cost is a fraction of the overall cost differences between the two options.

There are also start-up costs. Low-voltage techs are readily available in most markets. Medium-voltage techs, who require much more training, are far less common and cost more. You typically have to schedule them well in advance for start-up work.

.png?width=734&height=375&name=Group%209%20(1).png)

The cost of the drive:

480V Drive

$87,500 per pump

Savings with 480V VFD

$112,500

The costs of installation (medium-voltage costs less)

480V Drive

$62,000

Installation cost difference:

($17,000)

Total savings with 480V solution:

$95,500

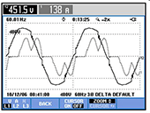

Operating Costs: 480V drives are more

efficient at lower horsepower

efficient at lower horsepower

Not only are 4160V drives more expensive initially, for applications of 1,000 hp or less, they are more expensive to operate. Considering that 800-1,000 hp motors are the most common in the oilfield, a medium-voltage drive is simply overkill.

Compare energy usage of our two options on one pump.

The cost of the drive:

4160V = 25.4kW

480V = 14.5kW

Energy savings = 25.4kW – 14.5kW = 10.9kW

Total savings on electrical per year:

$9,548.40 on just one pump.

$9,548.40 on just one pump.

At 10 cents per kWh, that is

$1.09 per hour

$26.16 per day

480V vs 4160V: A Five-Year

Cost-Savings Analysis

Cost-Savings Analysis

Total Savings on the Motor:

$8,890.00

Total Savings on the Drive + Installation:

$95,500.00

Total Operational Savings (x 5):

$47,742.00

Total savings for one pump:

$152,132.00

The Intangibles: fear, uncertainty

and distrust

Beyond the simple comparison of cost, there are a number of reasons why 480V drives are a much better option.

Uncertainty.

At SPOC, we stock every part for every drive we manufacture—for both new production and service calls. If something breaks, we can have a replacement part to you within 24 hours. More importantly, our suppliers stock parts all over the country. In many cases, we can have a part on site in an hour.

If you need a critical replacement part for a 4160V drive, you’ll wait weeks.

Fear and uncertainty breed distrust.

The simple truth is that the harsh conditions of the oilfield wreak havoc on all technology at some point. What happens when a drive is down and your production grinds to a halt? How quickly, and safely, can your supplier get you back up and running?

And one last thing: Innovation.

There are literally billions of low-voltage drives in use today. So guess where manufacturers are putting all of their innovation efforts? Almost all of the biggest advances in drives are happening in that arena. It’s simple economics. In the oilfield alone, 480V drives are far more common because they are an easier, smarter, more efficient method for controlling lower-horsepower motors. They just make sense.

And if these arguments aren’t convincing, we also offer DriveShield, the industry’s most comprehensive extended warranty.

Related Articles

Harmonics and Why You Have To Care

Producers up and down the Permian are receiving letters from their electric utilities stating that harmonics have become a serious problem that must be fixed. Read more...

Harmonics and Their Effects

Understanding the Cause, the Consequences, and the Cure. Read more...

Cancel Harmonics Using an Active Front End Drive

Increase efficiency, decrease maintenance costs, improve power quality upstream and across the distribution. Read more...

At SPOC Automation, we exist to apply

advanced automation technology to increase

your production while lowering your costs.

Ready to start saving on power?

Fill out the form to receive a PDF of The Math - 4160V vs 480V Whitepaper.