June 28, 2017 | Miller Coop

At SPOC Automation, we’re constantly seeking new ways to optimize your operations – to make your business more productive, more compliant, more cost effective and more rewarding. That’s why we listen to customers and develop solutions to solve their pressing problems. And often that means finding innovative ways to perform traditional tasks.

Take, for instance, your need to efficiently monitor operations. You’ve got well-trained pumpers to work your fields, and they seem to do a decent job. They make their rounds, check for changes, and quickly attend to issues they uncover. It’s all pretty routine.

But what happens if there’s a problem well and it’s the last one on their rounds? Will the pumper reach the well in time to tackle the emergent issue? Or are they spending too much time navigating remote roads? Do they routinely visit pumps that don’t need their attention?

Is there a better way to prioritize their day?

SPOC Automation devised a simple yet highly effective solution, to give your pumpers a faster way to detect the current state of each machine.

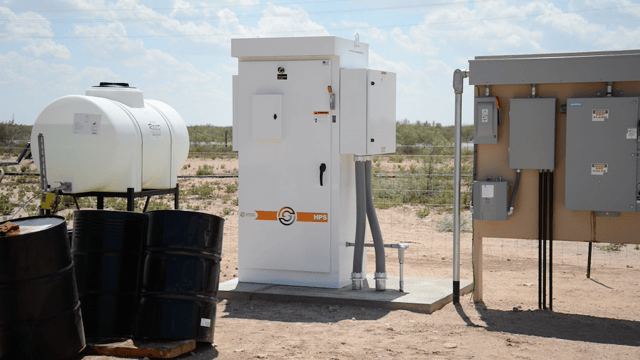

SPOC’s large VFD enclosures are engineered with LED lights that signal each pump’s condition from up to 100 yards away. At a glance, the pumper knows which pumps are good to go and which ones require some level of intervention.

Green light: The equipment is running, oil is flowing, and everything is operating as it should.

Amber light: The pump is not running right now but this shutdown is normal; the situation is routine.

Red light: A fault is detected and action is needed right away.

SPOC’s LED lights add another means to monitor operations, in addition to our local WiseGuy interface and remote Well Optix SCADA system. What’s more, the LED indicators come standard on every freestanding enclosure (and on other enclosures at the customer’s request).

With SPOC’s technology, your pumpers are primed to prioritize their day. Ready to learn more? Call us at 844.SPOC.VFD or email us: sales@spocautomation.com.