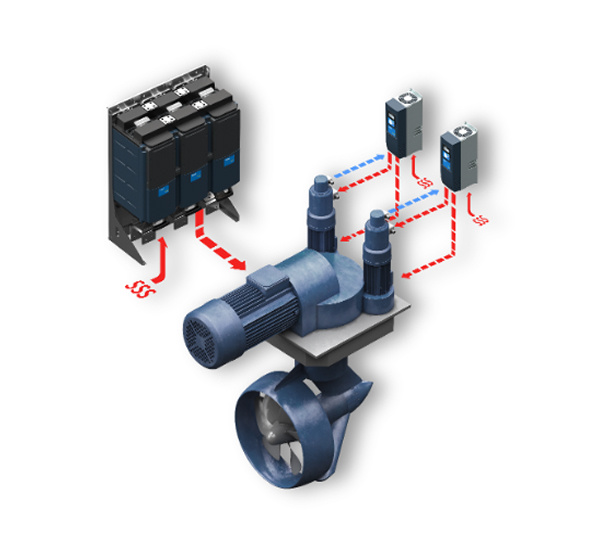

- Safe & precise maneuverability

- 20-30% energy savings compared to variable pitch thrusters

- Low maintenance cost

SUSTAINABLE OPERATIONAL AND ENVIRONMENTAL BENEFITS

From coastal vessels to global fleets, SPOC provides reliable, energy-efficient power systems that maximize performance and minimize emissions. Built to endure the harshest marine environments, our technology ensures continuous uptime, cost efficiency, and a sustainable maritime future.

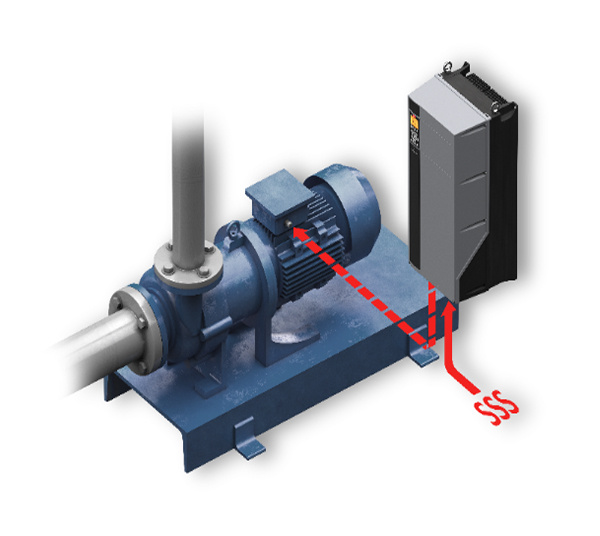

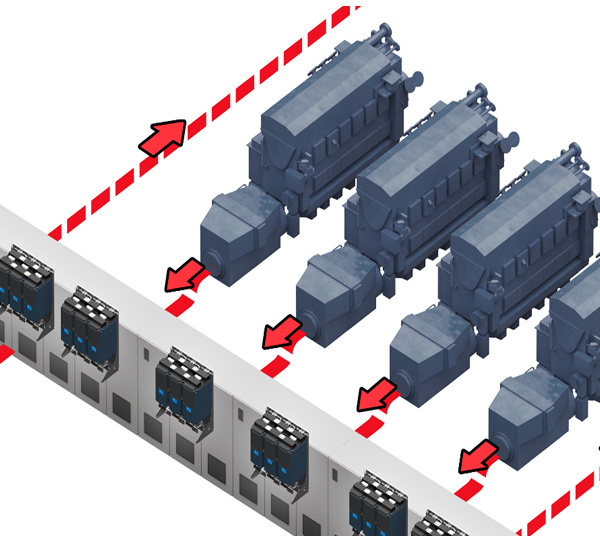

SPOC GRID

Drives for Pumps & Motors

SPOC has 25 years of experience building Variable Frequency Drive packages – with over 80,000 units installed in the harshest environments. Offering a full range of sizes from <1kW to 4 MW and voltages of 480, 690 VAC and up to 1100 VDC, we provide complete plug-and-play solutions including power electronics, circuit protection, and enclosures – as well as active and passive IEEE 519 compliant harmonic solutions. SPOC provides industry-leading 24/7 support and on-site service. Upgrade your power system to reduce inrush currents, minimize mechanical stress, and optimize your power usage and efficiency.

-1.png?width=555&height=243&name=Layer_1%20(2)-1.png)

.png)

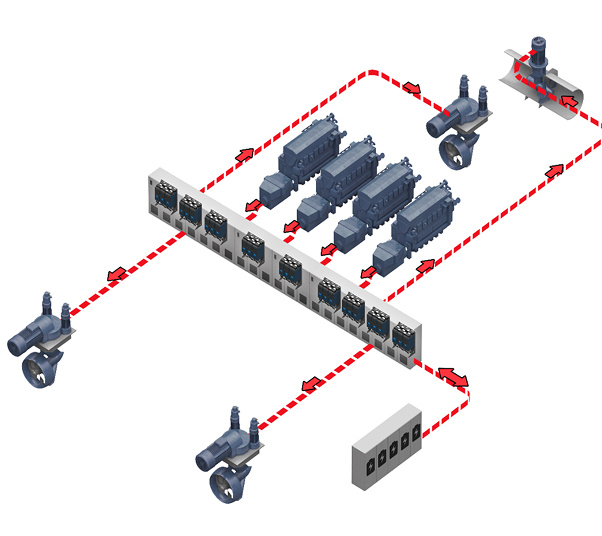

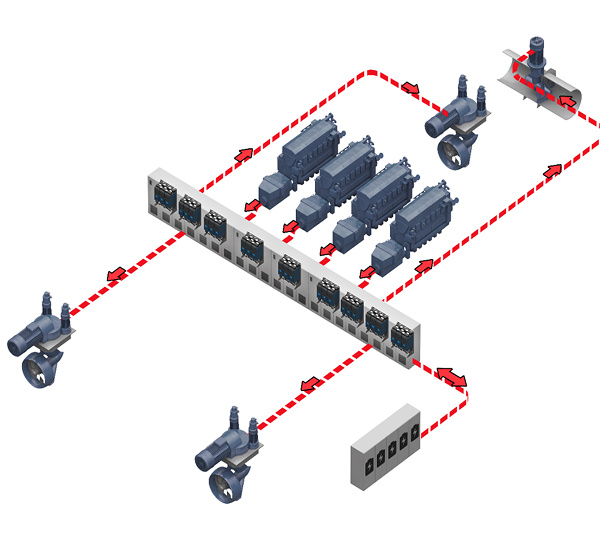

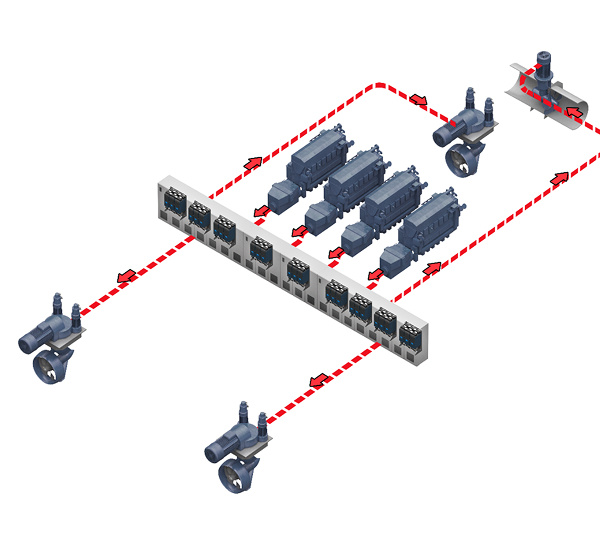

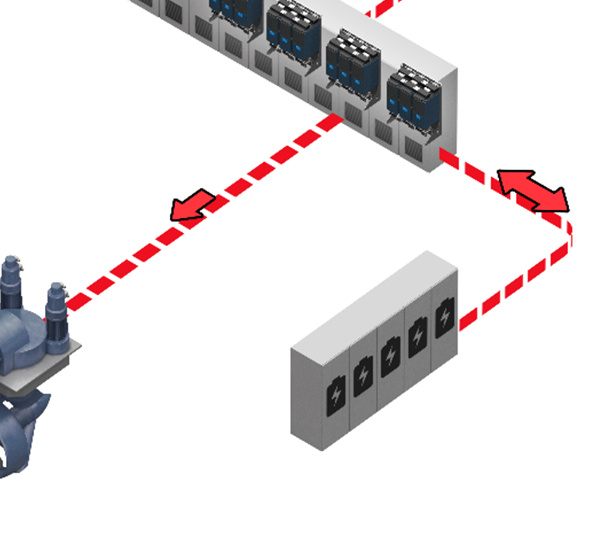

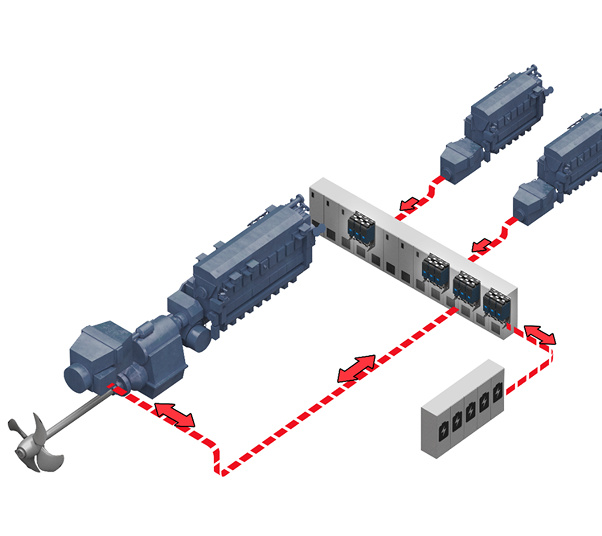

SPOC GRID

Marine Power Systems

SPOC engineers, manufactures, and services inverter-based marine power systems – providing you with purpose-built systems for the most demanding applications. Whether it’s for the power distribution system on a new build or retrofitting batteries to an existing vessel or VFD packages for all your auxiliary loads – SPOC has the solutions you need. We supply inverters, filters, chokes, circuit protection as well as custom enclosures and complete liquid cooling systems including chillers. Contact us to talk to an expert in adopting energy storage or advanced next-generation DC bus configurations to enhance redundancy, reliability, and efficiency. SPOC understands the critical nature of the marine industry and offers 24/7 service and support to our valued clients.

-1.png?width=479&height=221&name=Layer_1%20(3)-1.png)

Solving your Electrification Challenges with Purpose-Built Power Electronics Packages

Electric/Hybrid Systems Designed For You

At SPOC, our power conversion technology and expertise in a broad array of energy storage chemistries help you build ships with smarter, higher performing hybrid power systems that burn less diesel fuel and create fewer carbon emissions.

We have designed, delivered, and serviced inverters from 250 kW to 2 MW for DP-classed vessels (ABS, DNV, LR).

- Integrated chiller or connection to ship cooling

- Master or ship’s PMS control

- ESS and genset agnostic

- ABS, DNV, LR approval

- Shore power connection

- Liquid cooled or air cooled

- Active front end or 18 pulse for IEEE 519 harmonic mitigation

- System-matched magnetics and isolation transformers for voltage conditioning, common mode filtering, and galvanic isolation

- Inverters for propulsion or connection to ESS

- 100 - 5,000 kW power conversion

- DC grid architecture

- 480 V and 690 VAC

- Single or multiple battery strings integration

- Deck mounted or engine room installation

- Burn less fuel

- Size your generators to your optimal load profile

- Run generators at their most efficient load

- Reduce operating expenses

- Reduce emissions

Optimizing Vessel Performance

SPOC has the capability to work on a wide range of marine vessels, particularly those in industries requiring robust and efficient power systems.

- Offshore Vessels

- Merchant Vessels

- Inland Vessels

- Government Vessels

- FPSO

- Heavy Lift Vessel

- Subsea Construction

- Accommodation Vessel

- Jack-Up Rig

- Drillship

- Platform Supply Vessel

- Semi-Submersible Rig

- Diving Support Vessel

- Wind Turbine Installation

- Service Operations

- Well Intervention Vessel

- Anchor Handling Tug

FPSO

FPSOs are key to offshore oil and gas, requiring efficiency in processing, storage, and mobility. SPOC Marine’s hybrid solutions optimize gas compression, improve repositioning, and enhance onboard comfort. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Compressor Drives -

Efficient gas compression for storage.

Propulsion Control -

Energy-efficient repositioning.

HVAC Systems -

Comfortable working environment.

Heavy Lift Vessel

Offshore heavy lift vessels require stability, control, and efficiency to handle massive loads. SPOC Marine’s hybrid solutions enhance crane performance, improve thruster-driven stability, and optimize propulsion for efficient navigation. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Crane Drives -

High-capacity lifting and precision.

Thruster Drives -

Improved stability during heavy lifts.

Propulsion Control -

Efficient navigation with heavy loads.

Subsea Construction

Offshore subsea construction vessels need reliability and precision for complex tasks. SPOC Marine’s hybrid solutions boost efficiency, stability, and maneuverability for seamless operations in tough marine environments. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Crane Drives -

Smooth and efficient subsea lifting.

Thruster Drives -

Precise dynamic positioning.

Propulsion Control -

Efficient transit between sites.

Accommodation Vessel

Accommodation vessels require reliable power, mobility, and climate control to support crews at sea. SPOC Marine’s hybrid solutions ensure efficiency, stability, and comfort, creating a safer and more sustainable living environment. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

HVAC Systems -

Enhanced onboard comfort for crews.

Propulsion Control -

Efficient transit between sites.

Generator Optimization -

Stable power for utilities.

Jack-Up Rig

Jack-up rigs require precision for safe, efficient operations. SPOC Marine’s hybrid solutions improve movement, optimize station-keeping, and ensure precise ballast management for stability in tough offshore conditions. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Jacking Drives -

Efficient platform raising and lowering.

Thruster Drives -

Improved station-keeping during drilling.

Ballast Water Management -

Precise weight distribution.

Drillship

Drillships need stability, efficiency, and control for offshore operations. SPOC Marine’s hybrid solutions optimize mud circulation, improve station-keeping, and enhance onboard comfort in extreme conditions. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Mud Pump Control -

Efficient mud circulation for drilling.

Thruster Drives -

Station-keeping during operations.

HVAC Systems -

Comfortable living environment.

Platform Supply Vessel

Offshore supply vessels need reliability and precision in harsh conditions. SPOC Marine’s hybrid solutions boost fuel efficiency, maneuverability, crew comfort, and station-keeping while cutting diesel use. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Enhanced maneuverability and fuel efficiency.

Thruster Drives -

Precise station-keeping.

HVAC Systems -

Improved crew comfort.

Semi-Submersible Rig

Semi-submersible rigs need precise positioning and stability for safe operations. SPOC Marine’s hybrid solutions enhance energy-efficient relocation, optimize positioning, and ensure balanced ballast management for peak offshore performance. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Energy-efficient rig relocation.

Thruster Drives -

Accurate dynamic positioning.

Ballast Water Management -

Optimized platform stability.

Diving Support Vessel

Diving support vessels need reliable positioning, efficient navigation, and dependable air supply for safe operations. SPOC Marine’s hybrid solutions enhance performance, ensuring smooth and efficient support for underwater missions. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Station-keeping for safe diving operations.

Compressor Systems -

Reliable air supply for divers.

Propulsion Control -

Energy-efficient navigation.

Wind Turbine Installation

Wind turbine installation vessels need stability, control, and efficiency offshore. SPOC Marine’s hybrid solutions improve positioning, optimize lifting, and boost fuel efficiency for seamless turbine deployment. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Precise positioning for installations.

Crane Drives -

Efficient turbine lifting operations.

Propulsion Control -

Fuel savings during transit.

Service Operations

Service operations vessels need stability, control, and comfort for offshore tasks. SPOC Marine’s advanced systems improve positioning, optimize propulsion for fuel savings, and enhance the onboard climate. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Precise positioning for installations.

Propulsion Control -

Fuel savings during transit.

HVAC Systems -

Comfortable onboard climate.

Well Intervention Vessel

Well intervention vessels need stability, control, and efficiency for critical offshore operations. SPOC Marine’s hybrid solutions optimize positioning, enhance well pump performance, and improve fuel efficiency for seamless and reliable maintenance. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Enhanced positioning for operations.

Well Pump Systems -

Reliable well maintenance capabilities.

Propulsion Control -

Reduced fuel usage during transit.

Anchor Handling Tug

Anchor handling tugs need strength, precision, and efficiency for heavy tasks. SPOC Marine’s hybrid solutions boost towing power, optimize maneuverability, and ensure reliable anchor handling for peak performance. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Winch Drives -

Reliable anchor handling operations.

Propulsion Control -

Increased towing efficiency.

Thruster Drives -

Precise maneuverability.

- LNG Tanker

- Reefer Ship

- Cruise Ship

- Container Ship

- General Cargo Ship

- Feeder Ship

- Oil Tanker

- Bulk Carrier

- Ro-Ro Vessel

LNG Tanker

LNG tankers need precise cooling, efficient transfer, and stability. SPOC Marine’s hybrid solutions optimize compressors, enhance pumps, and ensure a comfortable climate for safe, reliable operations. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Auxiliary Pump Systems -

Improved LNG transfer efficiency.

HVAC Systems -

Comfortable onboard climate.

Reefer Ship

Reefer ships demand precise temperature control, fuel efficiency, and crew comfort. SPOC Marine’s hybrid solutions enhance refrigeration reliability, optimize propulsion, and improve onboard climate for smooth and efficient operations. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Compressor Drives -

Reliable refrigeration for cargo.

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

HVAC Systems -

Better onboard living environment.

Cruise Ship

Cruise ships require efficiency, precision, and comfort. SPOC Marine’s hybrid tech improves climate control, boosts maneuverability, and optimizes fuel use for a smoother, more sustainable voyage. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

HVAC Systems -

Enhanced passenger comfort.

Thruster Drives -

Precise maneuverability.

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Container Ship

Container ships demand fuel efficiency and cargo precision. SPOC Marine’s advanced propulsion cuts fuel costs, while optimized crane drives and HVAC systems improve loading efficiency and enhance crew comfort. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Crane Drives -

Efficient and smooth cargo handling.

HVAC Systems -

Improved conditions for crew.

General Cargo Ship

General cargo ships require efficiency and comfort. SPOC Marine’s hybrid tech improves fuel efficiency, optimizes cargo handling, and ensures a comfortable onboard environment for long voyages. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Crane Drives -

Improved cargo handling capabilities.

HVAC Systems -

Comfortable living environment.

Feeder Ship

Feeder ships need precise maneuverability and fuel efficiency. SPOC Marine’s hybrid tech optimizes propulsion, enhances thruster control, and improves crew comfort for efficient, cost-effective transit. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Thruster Drives -

Better port maneuverability.

HVAC Systems -

Enhanced crew comfort.

Oil Tanker

Oil tankers require precision and reliability. SPOC Marine optimizes pump control for safe transfer, enhances ballast water management for stability, and ensures a more comfortable onboard environment. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Pump Control -

Safe and efficient fluid transfer.

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Ballast Water Management -

Efficient weight distribution.

Bulk Carrier

Bulk carriers demand fuel efficiency and strict regulatory compliance. SPOC Marine optimizes pumping systems, ensures precise ballast management, and enhances propulsion for cost-effective, smooth operations. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Pumping Systems -

Energy-efficient fluid handling.

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Energy-efficient cargo handling -

Demand-based motor speed adjustment..

Ro-Ro Vessel

Ro-Ro vessels need smooth cargo movement and efficiency. SPOC Marine enhances ramp operations, ensures a controlled onboard climate, and improves propulsion to cut fuel use and emissions. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Ramp Winch Systems -

Smooth and reliable operations.

HVAC Systems -

Optimized onboard climate control.

Propulsion Control -

Lower fuel consumption and emissions.

- Push Boat

- River Ferry

- Fishing Boat

- Tug

- Dredger

Push Boat

Push boats and tow boats need efficient propulsion for demanding routes. SPOC Marine’s solutions improve fuel economy, optimize power, and enhance crew comfort for reliable long-haul performance. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Reduced fuel usage and emissions.

Generator Optimization -

Consistent and efficient power output.

HVAC Systems -

Improved onboard comfort.

River Ferry

River ferries require efficiency, reliability, and passenger comfort. SPOC Marine optimizes propulsion, enhances climate control, and reduces energy costs for safe, sustainable, and continuous operation. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Efficient and reliable operations.

HVAC Systems -

Enhanced passenger comfort.

Generator Optimization -

Reduced operational costs.

Fishing Boat

Fishing vessels need efficiency, control, and reliability to maximize productivity at sea. SPOC Marine’s hybrid solutions optimize fuel use, improve hydraulic precision for net handling, and ensure a stable power supply for critical onboard systems. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Improved fuel economy.

Hydraulic Systems -

Better net handling.

Generator Optimization -

Reliable power for equipment.

Tug

Tugboats need responsive control, strong towing, and consistent power. SPOC Marine’s hybrid solutions improve propulsion, ensure smooth winch performance, and provide stable energy for operations. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Improved efficiency and response.

Winch Drives -

Smooth and reliable towing operations.

Generator Optimization -

Stable power for instruments.

Dredger

Dredgers need precision, durability, and efficiency for demanding operations. SPOC Marine optimizes cutterhead control, winch positioning, and discharge handling to maximize productivity and reliability. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Cutterhead Motors -

Optimized speed and torque for efficient digging.

Winches & Hoists -

Smooth positioning for safety and reliability.

Conveyors & Discharge Systems -

Controlled handling to reduce spillage.

- Hospital Ship

- Patrol Boat

- Icebreaker

- Survey Vessel

- Firefighting Vessel

- Research Vessel

- Fleet Oiler

- Dry Cargo Ship

Hospital Ship

Hospital ships need precision and reliability for critical care. SPOC Marine’s hybrid solutions enhance climate control, ensure stable power for medical equipment, and provide reliable propulsion for urgent missions. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

HVAC Systems -

Enhanced climate control for patients.

Propulsion Control -

Reliable transit in emergencies.

Generator Optimization -

Stable power for medical equipment.

Patrol Boat

Patrol boats operate in high-stakes conditions requiring speed and efficiency. SPOC Marine’s hybrid solutions improve propulsion for rapid response, ensure reliable power, and maintain a stable onboard climate. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Propulsion Control -

Enhanced speed and response efficiency.

Generator Optimization -

Improved operational reliability.

HVAC Systems -

Comfortable onboard environment.

Icebreaker

Icebreakers need force and precision to navigate harsh environments. SPOC Marine’s hybrid solutions provide high-torque propulsion, advanced thruster control, and optimized power for efficiency and reliability. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Hybrid Shaft Generator -

Increases fuel efficiency and lowers emissions.

Thruster Drives -

Enhanced maneuverability.

Generator Optimization -

Fuel savings and reliable power output.

Survey Vessel

Survey vessels need precise maneuverability and steady power for sensitive equipment. SPOC Marine’s technology improves positioning, optimizes propulsion, and ensures a reliable energy supply for accurate data collection. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Precise positioning during surveys.

Propulsion Control -

Fuel-efficient navigation.

Generator Optimization -

Stable power for instruments

Firefighting Vessel

Firefighting vessels require quick deployment and strong suppression systems. SPOC Marine’s technology enhances water pump efficiency, ensures climate control, and provides dependable propulsion for emergencies. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Water Pump Control -

High-efficiency firefighting capabilities.

HVAC Systems -

Optimized onboard climate control.

Propulsion Control -

Reliable transit to emergency sites.

Research Vessel

Research vessels need reliable systems for extended operations at sea. SPOC Marine’s advanced solutions ensure precise equipment deployment, fuel-efficient navigation, and a comfortable onboard environment for crews. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Winch Systems -

Precise deployment of equipment.

Propulsion Control -

Energy-efficient long-distance navigation.

HVAC Systems -

Comfortable work environment.

Fleet Oiler

Fleet oilers must enable seamless fuel and cargo transfer. SPOC Marine’s systems improve winch precision, optimize propulsion for fuel savings, and streamline cargo pump operations for smooth, efficient transfers. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Thruster Drives -

Enhanced maneuverability.

HVAC Systems -

Comfortable work environment.

Cargo Pump Systems -

Improved cargo transfer efficiency.

Dry Cargo Ship

Dry cargo ships need efficiency, precision, and reliable power. SPOC Marine’s systems optimize propulsion for fuel savings, enhance winch performance for cargo handling, and ensure a stable environment for crew comfort. These are some examples of electrification/hybrid solutions we provide for your vessel.

Applications:

Winch Systems -

Precise deployment of equipment.

Thruster Drives -

Enhanced maneuverability.

Cargo Pump Systems -

Improved cargo transfer efficiency.

Applications & products

Every Deck, Every Hull, Every Corner

Our technology optimizes energy use, reduces emissions, and extends equipment life, delivering smarter, more sustainable performance throughout your vessel.

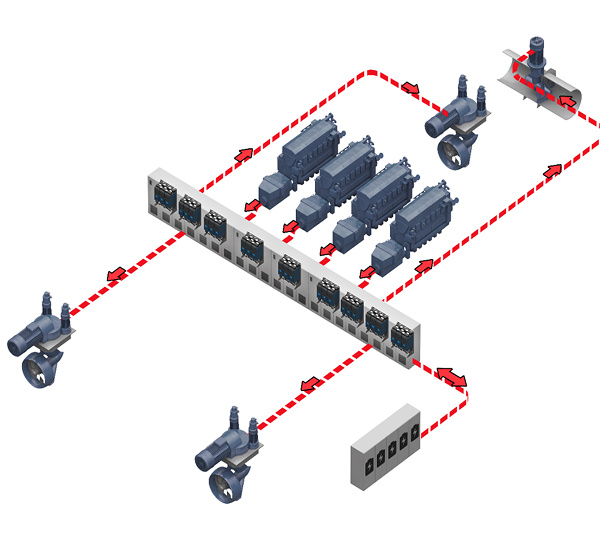

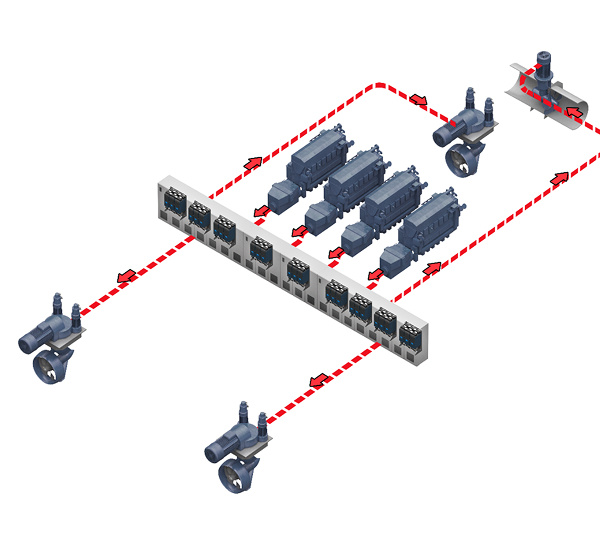

Thruster

Process Pumping

- Automatic energy optimizer saving additional 5-15%

- Payback down to 12 months using speed-controlled pump

- Built-in pump features

Hybrid Propulsion

- Better dynamics

- Performance optimization

- Ability to stop engines

AC Grid

- Lower insulation and safety protection

- Less expensive fuse protection

Diesel Electric Propulsion

- Reduce fuel use and emissions

- Maximize efficiency with variable-speed propellers

- Ensure reliability with built-in redundancy

Steering Gear

- Fast & precise rudder positioning

- Live backup system

- Over 70% energy savings compared to fixed-speed hydraulic pump system

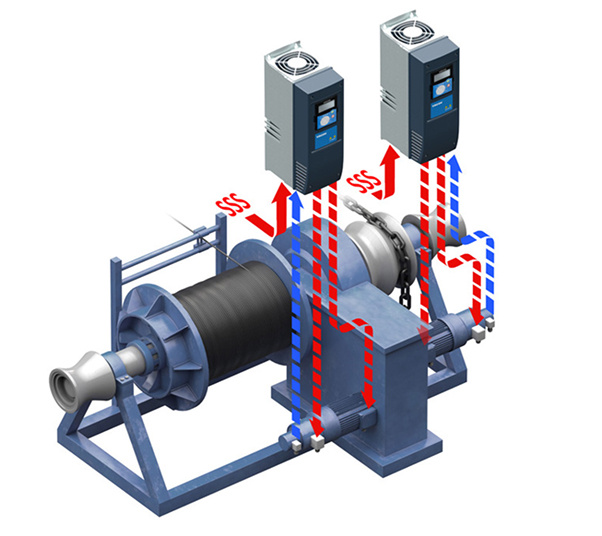

Winch

- No risk hydraulic fluid leakage

- Low energy consumption and no standby losses

- Low acoustic noise level

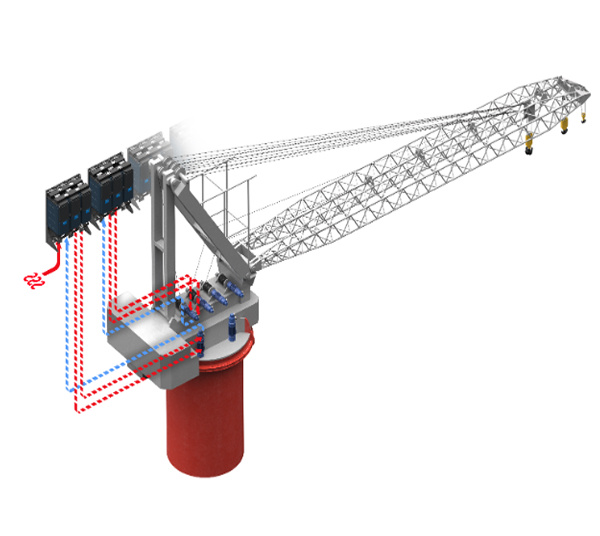

Crane

- Elimination of hydraulic fluid leakages

- Only marginal losses in standby mode

- High efficiency during normal operation

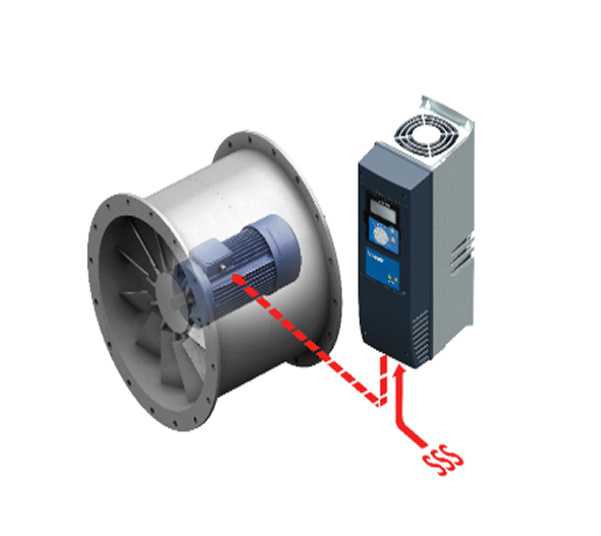

Fans and HVAC

- Typically 30-50% energy savings

- Reduced acoustic noise

- Fire mode improves safety in HVAC system

Cooling Water System

- Optimize cooling by adjusting seawater pump flow to demand

- Minimize energy waste with precise control

- Achieve payback in under 12 months

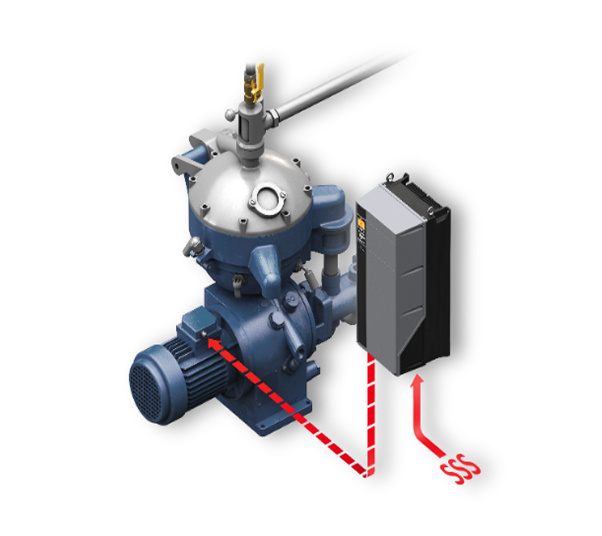

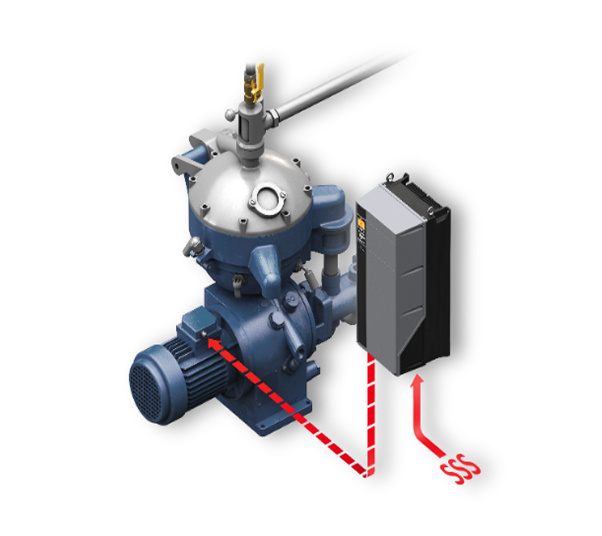

Separators

- High operation reliability

- Low maintenance cost

- Maximum speed safety function without external speed sensor

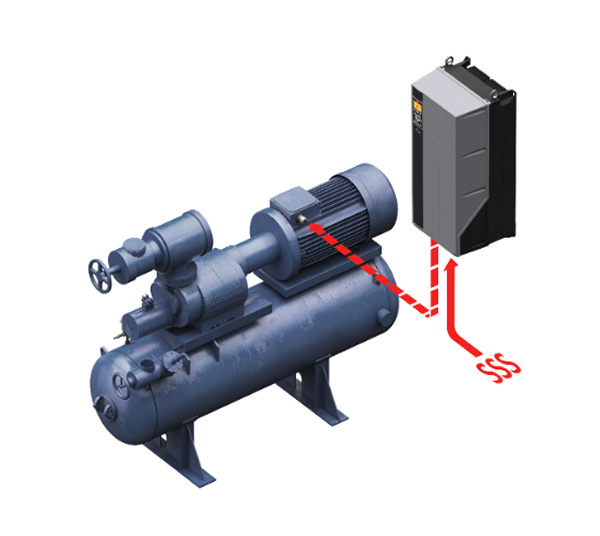

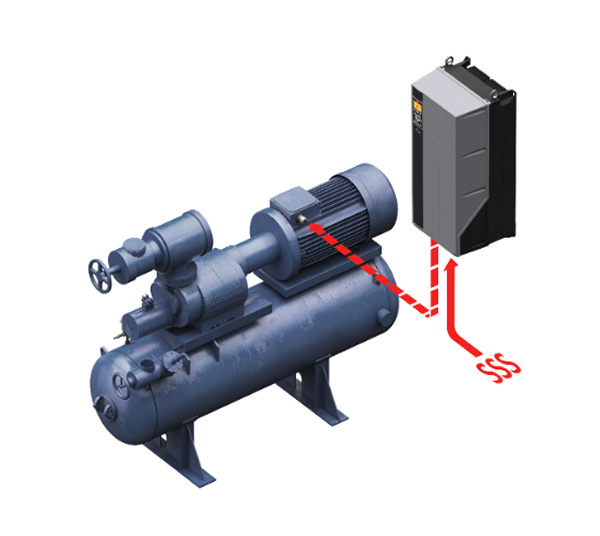

Refrigeration Compressors

- Improved efficiency

- Built-in compressor control functions

- Improved compressor lifetime

Battery Energy Storage

- Better dynamics

- Optimization

- Downsize main engine

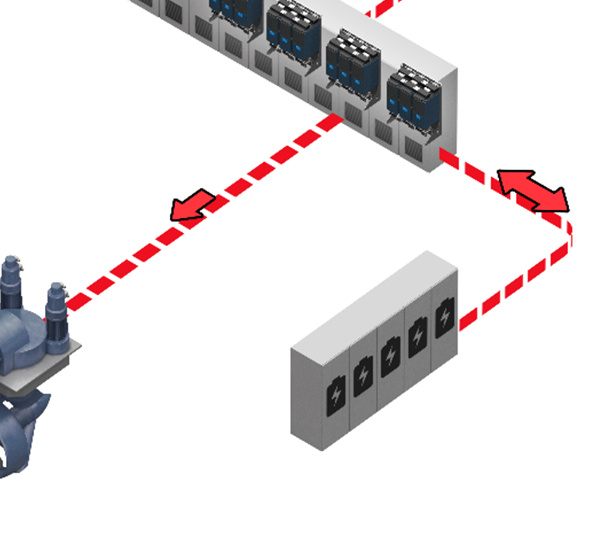

DC Grid

- Common DC bus optimizes power conversion with fewer power conversion modules required and reduced cabling costs

Hybrid Shaft Generator

- Battery energy storage peak shaving system allows smaller and more efficient engines

Shore Power and Charging Supplies

- Very high system efficiency and low standby losses

Vacon NXP Air Cooled

- Serves a broad range of demanding industrial applications, focusing on higher power sizes and system drives

Grid Converter

- For advanced AC/DC power conversion

Active Front End (AFE)

.jpg)

- Bidirectional low harmonic supply unit for motor drive applications

DC-DC Converter

- Tap into the benefits of electrification

Motor Inverter

- Bidirectional DC-fed power inverter for the supply and control of AC motors and generators

Vacon NXP DC Guard

- Ensure fast disconnection and full selectivity between DC grids

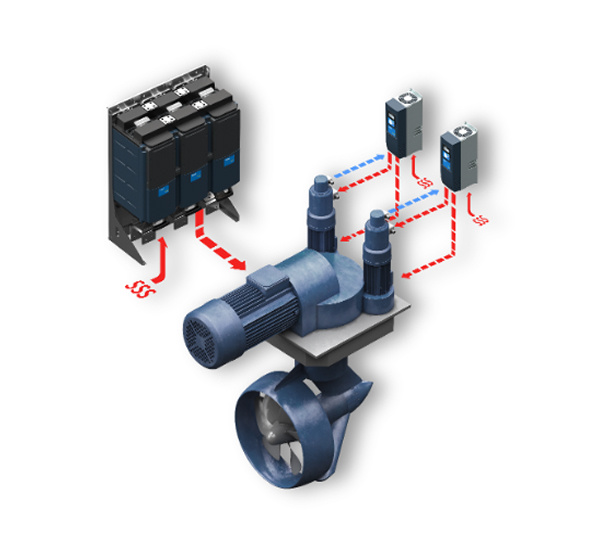

Thruster

Thruster

Achieve precision at speed and high torque

- Precise maneuverability in all seas thanks to high torque capabilities, speed, and accuracy

- AC-drive controlled variable speed propellers with fixed pitch are typically 20-30% more energy-efficient than fixed speed variable pitch propellers, which waste approximately 20% of the power at zero thrust

- Large energy savings potential for dynamic positioning systems operating for long periods

- Variable speed propellers use 50% less power than hydraulic alternative

Process Pumping

Process Pumping

Flexible, compact, robust solutions

Drives control pumps to match actual process need, leading to reduced energy consumption. Reducing the speed by 20% reduces the power consumption by 50%. AC drives also protect the pump, extending service intervals and total lifetime.

Hybrid Propulsion

Hybrid Propulsion

Clean air thanks to less emissions

New-build or retrofitted battery energy storage gives the vessel:

- Better dynamics

- Performance optimization

- Ability to stop engines

- Downsizable main engine

- Stable average power from main engine and dynamic peaks from battery

- Integrate DC Grid architecture with batteries, fuel cells, or other stored energy

AC Grid

AC Grid

Established IT grid technology

Traditional AC grids in the form of IT grid are well established technology and run at lower voltages than DC grids, meaning:

- Lower insulation and safety protection

- Less expensive fuse protection

- Mature marine standards exist for AC grids

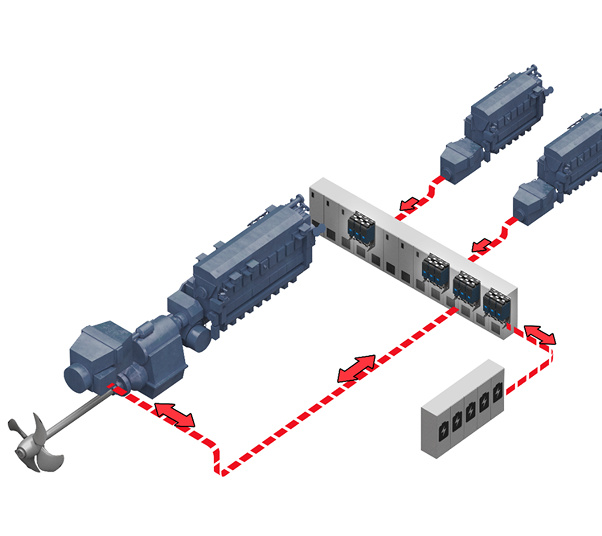

Diesel Electric Propulsion

Diesel Electric Propulsion

Power generation and power conversion

- Drives for power generation, electric grid power conversion, electric motor propulsion, and a wide variety of thrusters

- Reduce complexity as all products have marine-type approvals

Steering Gear

Steering Gear

More speed and accuracy – using less power

- Fast and accurate rudder positioning due to variable speed hydraulic pump system and rotary vane hydraulic actuator

- Extremely safe due to live backup system

- Hydraulic pumps run only when the vessel is changing course, reducing energy consumption by >70% compared to a fixed speed hydraulic pump system

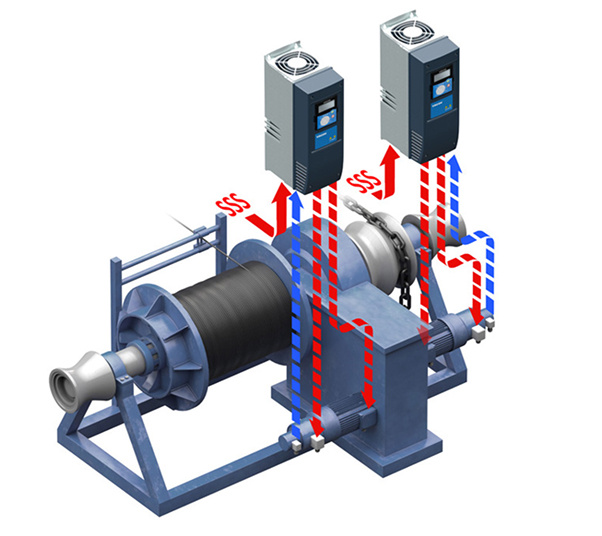

Winch

Winch

Improve safety and save 30% on energy consumption

- Up to 30% energy savings compared with hydraulic alternative

- Low acoustic noise level

- No risk of hydraulic oil leaks

- Excellent speed and tension control range – both in open and closed loop applications

- Load sharing between multiple motors, with droop function

- Inertia-compensated torque readout for wire tension calculation

- Advanced mechanical brake control eases mechanical stress on both gear and brake

- High safety due to advanced brake monitoring functions

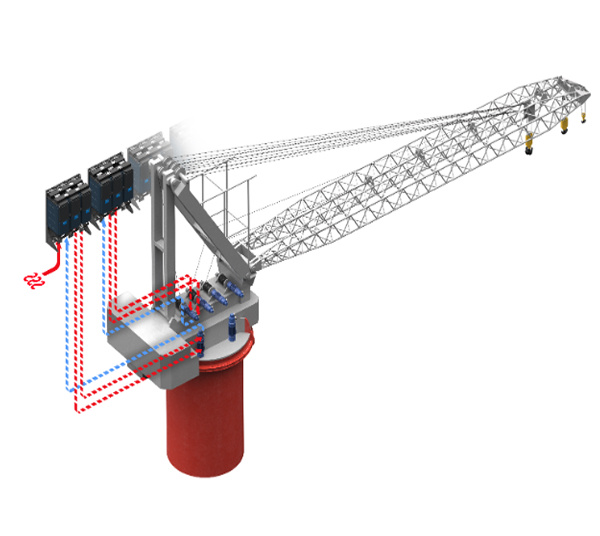

Crane

Crane

Accurate and reliable lifting onboard and onshore

- Typically 15% shorter cycle time, due to faster movements

- Elimination of hydraulic fluid leakages and overheating

- Losses only marginal in standby mode

- High availability compared to traditional hydraulic cranes

- Hybrid solution

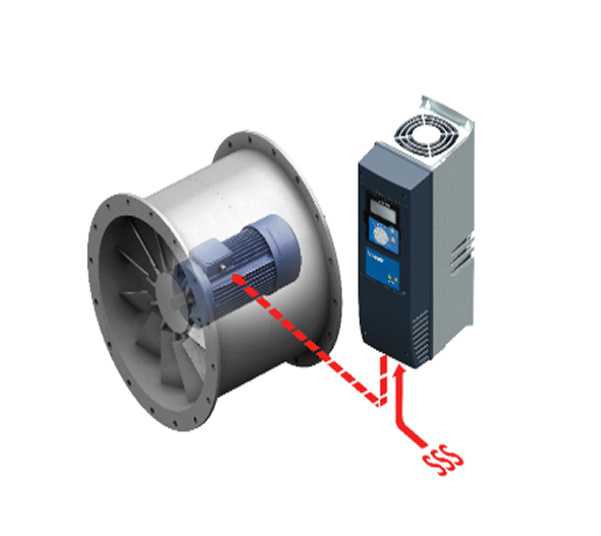

Fans and HVAC

Fans and HVAC

Reduce energy consumption

- Drives control the pump and fan speed to match actual demand

- Load and ambient temperature dependent capacity control save 30-50% energy for ventilation of machine rooms and accommodation

- Reduce the speed by 20% to reduce the power consumption by 50%

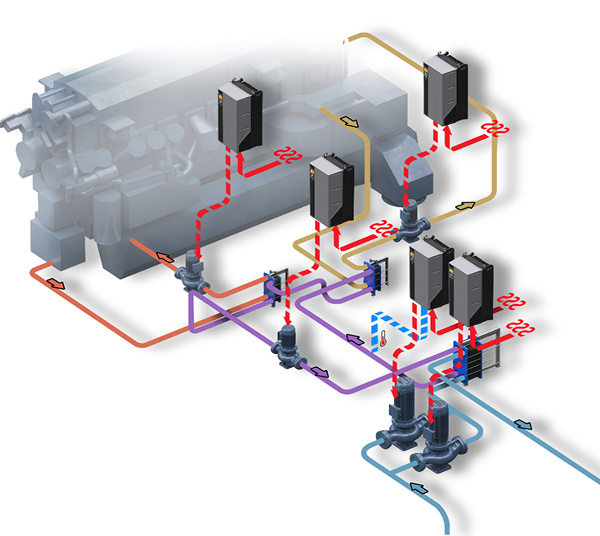

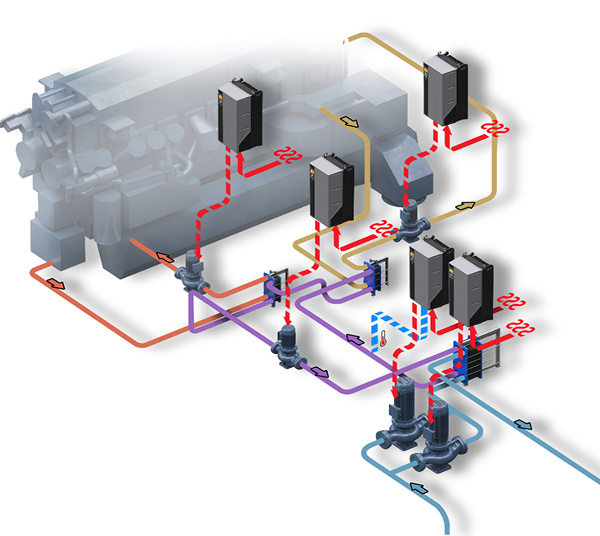

Cooling Water System

Cooling Water System

Match flow demand and save

- Cooling water systems are designed for 100% load at 32oC seawater temperature

- The maximum cooling capacity is only rarely needed as few ships sail in equatorial waters and at speed all the time

- Drives control seawater pumps to match actual flow demand to deliver 36-38oC water out of the central cooler

- Freshwater pumps are typically controlled by differential pressure

Separators

Separators

Drives protect and optimize uptime

- Ensure reliable operation of bilge water, fuel conditioning, and oil centrifuge separators

- Smooth acceleration protects gearbox and high speed bowl bearings

- Protect the separator against discharge shock loads

- Fast recovery from power outage:

- Drive catches the spinning separator on the fly

- AC flux braking eliminates the need for resistors

- Drive catches the spinning separator on the fly

Refrigeration Compressors

Refrigeration Compressors

Screw, reciprocating, and scroll compressors

- Speed-controlled screw compressors typically use 15% less energy than traditional screw compressors with slide valve control alone

- Optimized start/stop cycles reduce wear and tear on the compressor

- Reciprocating piston compressors are suitable for variable speed control to improve COP at part loads

- Drives are particularly effective for scroll compressor operation, enhancing overall efficiency

Battery Energy Storage

Battery Energy Storage

Save up to 30% on fuel consumption

Add e-storage and use it as an active component to achieve less fuel consumption and less emissions

- Better dynamics

- Optimization

- Possibility to stop engines

- Downsize main engine

- Stable average power from main engine and dynamic peaks from battery

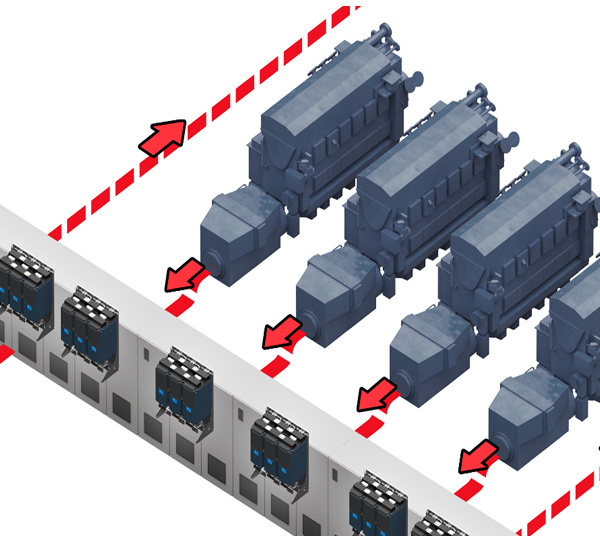

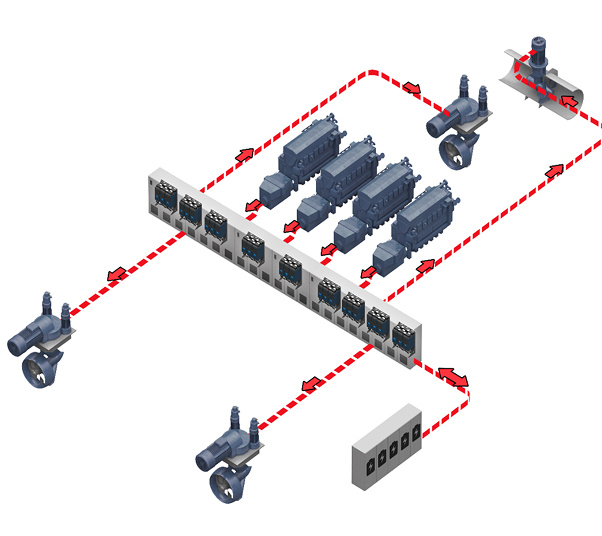

DC Grid

DC Grid

Greater efficiency, easier battery integration

A DC grid on board the vessel improves overall efficiency and reliability. Integration of energy storage systems becomes easier.

- Common DC bus optimizes power conversion, with fewer power conversion modules required and reduced cabling costs

- Floating voltage/frequency auxiliary generators ensure maximum efficiency

- Micro grid converters produce clean AC power

- Battery energy storage peak shaving system allows smaller and more efficient engines

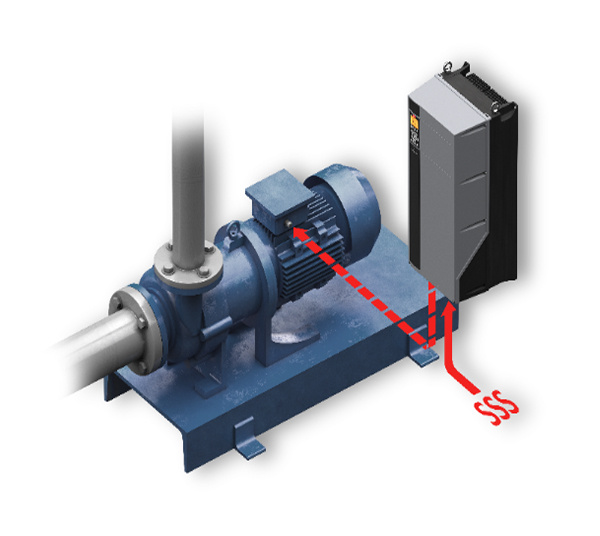

Hybrid Shaft Generator

Hybrid Shaft Generator

Save up to 30% on fuel consumption

- Variable speed shaft generator/motor

- PTO/PTI (Power Take Out, Power Take In), Boost, and Take Me to Harbor function

- Common DC bus optimizes power conversion

- Floating voltage/frequency auxiliary generators ensure maximum efficiency

- Micro grid converters produce clean AC power

- Battery energy storage peak shaving system allows smaller and more efficient engines.

Shore Power and Charging Supplies

Shore Power and Charging Supplies

Reduce emissions by shutting down auxiliary generators

- Burning fuel during port stays is a significant sources of local air pollution

- Shore power supply ensures 60 Hz clean AC power for the ship’s grid. Ability to synchronize and connect to DC grid for charging applications

- Ship’s equipment is protected with low harmonic AFE technology

- Automatically synchronizes to the ship’s grid thanks to micro grid inverter

- Very high system efficiency and low standby losses

Vacon NXP Air Cooled

Vacon NXP Air Cooled

Serves a broad range of demanding industrial applications, focusing on higher power sizes and system drives

Power range

- 3 x 380 – 500 V / 132 – 1200 kW

- 3 x 525 – 690 V / 110 – 2000 kW

Power range - AFE supply

- 3 x 380 – 500 V / 132 – 1200 kW

- 3 x 525 – 690 V / 110 – 2000 kW

Power range - Low harmonic, Active Filter supplies

- 400 V / 132 – 560 kW

- 500 V* / 132 – 560 kW

- 690 V / 110 – 800 kW

*Requires 690 V active filter

Grid Converter

Grid Converter

For advanced AC/DC power conversion

Ratings

- 236-5750 A IL, +10% overload 1 min/5 min

- 525-690 VAC / 640-1100 VDC

- 380-500 VAC / 465-800 VDC

- 45-66 Hz Grid frequency (25-70 Hz with derating)

- THDi < 5% (< 3% with dedicated transformer)

- Adjustable power factor

Active Front End (AFE)

.jpg)

Active Front End (AFE)

Bidirectional low harmonic supply unit for motor drive applications

Ratings

- 236-5750 A IL, +10% overload 1 min/5 min

- 525-690 VAC / 640-1100 VDC

- 380-500 VAC / 465-800 VDC

- 45-66 Hz Grid frequency

- THDi <5%

- Fundamental power factor cos = 1, adjustable reactive current set point

DC-DC Converter

DC-DC Converter

Tap into the benefits of electrification

Ratings

- 300-3600 A IL, +10% overload 1 min/5 min

- 640-1100 VDC bus

- 465-800 VDC bus

- DC Source voltage range 3-100% of DC bus voltage. Full control performance 3-97% of DC bus voltage

Motor Inverter

Motor Inverter

Bidirectional DC-fed power inverter for the supply and control of AC motors and generators

Ratings

- 170-6400 A IL, +10% overload 1 min/5 min

- 525-690 VAC / 640-1100 VDC

- 380-500 VAC / 465-800 VDC

- Output frequency: 0-599 Hz

- dU/dt filter up to 250 Hz with derating

- Sine wave filter up to 300 Hz with derating

- Switching frequency: 2-10 kHz. Nominal 3 kHz, Sine wave filter 8 kHz

Vacon NXP DC Guard

Vacon NXP DC Guard

Ensure fast disconnection and full selectivity between DC grids

Current range

- 465 – 800 VDC / 3 – 4140 A

- 640 – 1100 VDC / 4 – 3100 A

latest industry trends

Navigating the Complexity of Electrification

SPOC

On Batteries

Energy vs. Power: A Maritime Example

Technologist

MEET THE TEAM

THE MINDS BEHIND OUR INNOVATION

Aftermarket Support

Comprehensive Support Every Step of the Way

At SPOC, we are committed to being your hands-on partner throughout the entire lifespan of your equipment. Whether you need fast repairs, preventative maintenance, or technical advice, our professional field service team delivers reliable solutions when you need them most. From 24/7 tech support via phone, live chat, or video, we ensure your operations run seamlessly. We prioritize speed—offering expedited shipping and quick-response field service teams—so you can stay focused on your business without unnecessary downtime.

we are defined by our core values

If you want to know what makes SPOC a special place, understand these five core aspects of our beliefs.